Our Socks Company Factory Mission Is To Harness Our Productivity And Creativity Into Perfect Socks

Zhejiang Kaite Knitting Co., Ltd. is a production and trading company that integrates R&D and production.

Committed to the production and development of various types of socks, specializing in the production of daily socks such as men’s and women’s socks, as well as functional socks such as football socks, basketball socks, and pressure socks. Our company was established in 2010. The headquarters is located in Zhuji City, Zhejiang Province, China, with convenient transportation and beautiful environment. The company’s products meet international quality standards and have passed ISO 9001:2015 quality system certification, as well as BSCI, SEDEX and other international business social standard certifications. The company always adheres to the principle of quality first and service first. We sincerely look forward to your negotiation and ordering.

Here you can have a detailed understanding of us and tell us about your socks idea, Or see our previous socks work.

Kaite Socks Factory Production Process

Socks design:

All sock production starts with the design. The designs, colors, and sizes of the socks produced come from the design, but not all designs can be made into socks. The current technology is somewhat limited. We will treat customers with socks. The design proposes some suggestions so that the design can be made into real socks. The perfect design will bring a lot of convenience to the production.

Preparation of raw materials:

According to the customer’s requirements and design drawings, we prepare yarn raw materials, such as veil, polyester, chemical fiber, etc. If needed, dying of yarn is also required. The quality and cost of socks have a lot to do with raw materials. We will target Customers need to choose the right yarn.

Understand the materials used in socks

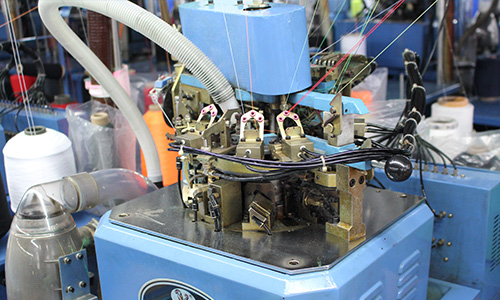

Convert to machine code:

The sock design provided by the customer cannot be directly read by the sock knitting machine. It needs a professional code to be used for the sock knitting machine. Each pixel will be converted into a needle of the machine. Different machines have a different number of needles. Commonly there are 96N, 144N, 168N, 200N, etc. Due to the limitation of the number of stitches, the socks cannot show a fine pattern or a gradient.

In step one, we have prepared the yarns and made the machine code. Our socks factory need to make the yarns of each color weave the socks in a certain order. It looks very tedious. The weaving socks machine will help us to get these. We are not Need to worry too much.

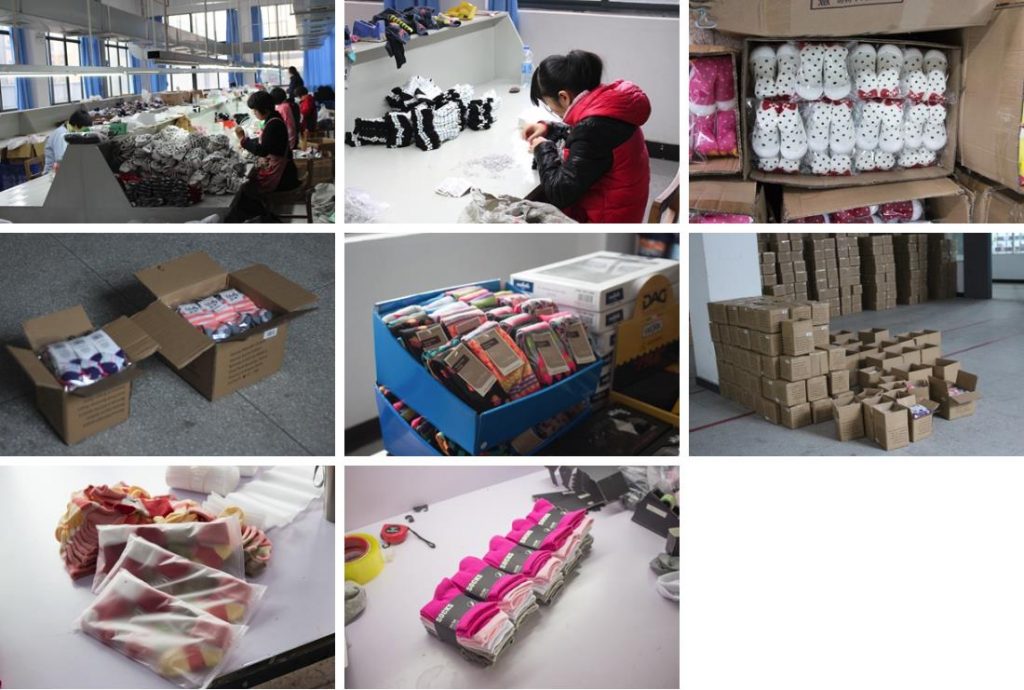

Through this step, we already have a prototype of socks, but we still have some work to do, check the sock’s thread, trim, and some color corrections.

Socks: Through the production of hosiery machines, socks are just a cylindrical tube that is not really finished. We need to connect the toes together by a sewing machine. Usually, this step is done by the machine and sometimes it is done manually. This will take a lot of time, but this time is worth it. Our workers will find some defective socks during the sewing process and remove them.

Other treatment processes:

Customers can add more crafts to make socks more attractive, Our sock company can add embroidered logos/logos, can print, add glue to increase slip resistance, or sew foot mats…

Styling fixes the socks on the same template. Under certain pressure/temperature and humidity, the socks will become more flexible. Styling keeps socks flat and uniform in shape for easier pairing and packaging.

Based on the experience of our sock company, Custom labels can be produced at the same time as the production of socks. This saves a lot of time. We have cooperating printers and customers do not have to worry about the production of labels or labels. Of course, customers can choose their own printing company, we will make a good tag to us and we will fix it on the socks.

The packaging of the socks includes the matching of the socks, affixing their own labels, and at the same time allowing the final quality inspection of the socks.

Sock Company Technology

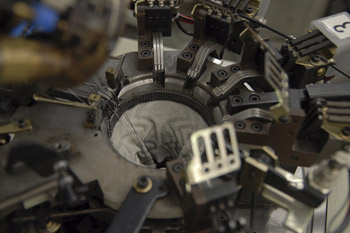

Hand linking:

Hand linking is a technique where the craftsperson matches every single stitch that is sewn together to close the toe of the sock. In the case of high-gauge socks, such as business socks, there is demand for socks with the lack of ridge of leftover material at the toe, and so this method continues to be used even now. Socks that use this process will be more comfortable to wear.

Socks Needles Count:

Socks specifications of needles. For most sock company, there are 120 needles, 144 needles, 168 needles, 200 needles. 96 needle and 72 needles are very seldom to use, there’s no such demand and most machines are not computerized, which mainly for producing the thick needle socks; 220 needles mainly to produce high-end sock which has a high requirement for the material like mercerized wool.

Terry socks :

The terry socks are also called half-sleeve socks, and the interior is the same as the towel, which is comfortable to wear. The exterior is the same as cotton socks. Comfortable to absorb sweat, suitable for people who love sports. Towel socks are not very hot in summer because of their fluffy weaving process and good breathability of cotton. They also help to absorb sweat and perspiration and keep the movement comfortable and hygienic.

Machine embroidery:

Machine embroidery is an embroidery process whereby a sewing machine or embroidery machine is used to create patterns on textiles. Machine embroidery can be used to weave beautiful patterns on socks.

Non-skid Rubber:

Our sock company offers the Non-skid Rubber process. Place a rubber bumper on the bottom of the sock, Make socks play a non-slip effect. It makes it easy to move, and suitable for walking on long roads and sports.

Socks Factory Real Media

Video

Sample workshop photos

Knitting workshop photos

Sewing and Linking

Boarding socks

Socks packing

Other photos